STEP Technology® - the whole sample from top to bottom instantaneously

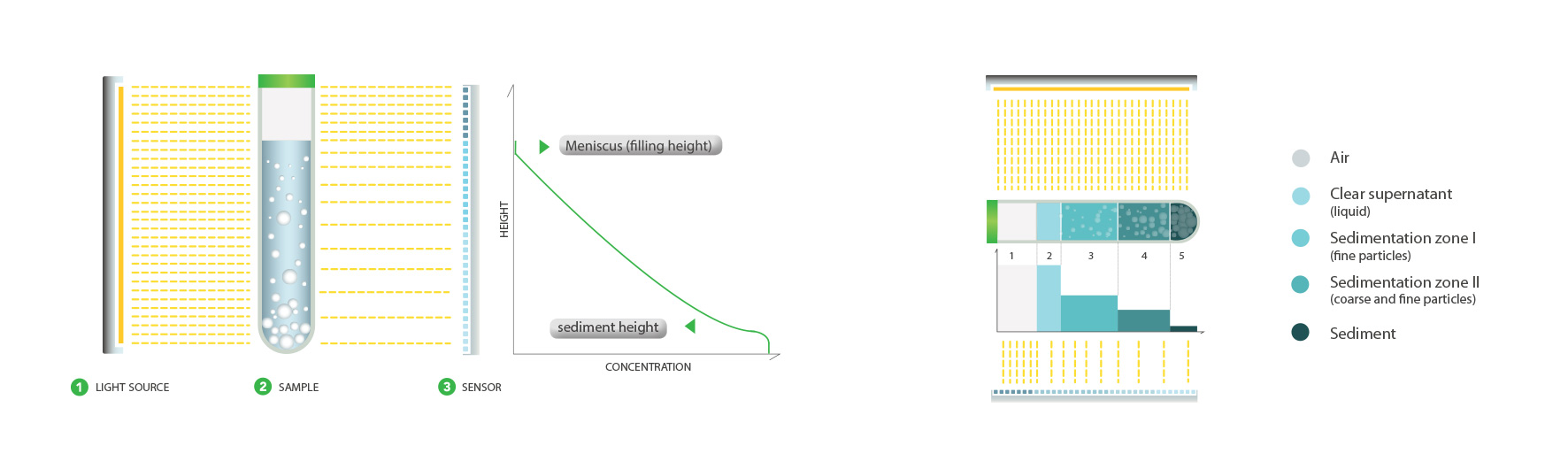

At the heart of each instrument is the cutting-edge STEP Technology, which is short for Space- and Time-resolved Extinction Profiles. It is the only technology that allows you to analyze your whole sample instantaneously from top to bottom.

So you can understand every aspect of your dispersion, emulsion, and suspension. You can easily, accurately, quickly measure and quantify any and all dispersion stability or instability phenomena. Be it a change in the particle size distribution, an increase in the creaming rate of your emulsion, or sedimentation of your suspension.

STEP-Technology permits to obtain Space- and Time-resolved Extinction Profiles over the entire sample length of up to 12 different samples simultaneously. Parallel light (I0) illuminates the entire sample cell and the transmitted light I is detected by thousands of sensors arranged linearly across your whole sample from top to bottom with a microscale resolution. Transmission is converted into extinction by lg I/I0 and particle concentration may be calculated. STEP-Technology gives also high flexibility to use different cells to match specific sample properties.

------------------------------------------------------------------------------------------------------------------------------------------------------------

By means of the comprehensive software SEPView the light intensity can be adjusted to the corresponding sample turbidity. Transmission profils are recorded as fast as each second or with time intervalls up to hours, displayed as a sequence on the screen. Transmission date are automatically stored in a special designed database, together with all instrument settings and actual calibration data.

------------------------------------------------------------------------------------------------------------------------------------------------------------

The speed of the centrifuge can be set at a constant value or programmed to change during the measurement in the range from 200 rpm to 4000 rpm. These rpm-values correspond to relative centrifugal forces (RCF) at the bottom of the cell of 5 to 2300 (RCF = centrifugal acceleration/earth gravity). Built-in temperature control covers all present and future applications.

------------------------------------------------------------------------------------------------------------------------------------------------------------

Evaluation Features: The evolution of the transmission profiles contains the complete information on the kinetics of any concentration changes due to creaming, sedimentation, flocculation, coalescence or phase separation. Based on these space- and time-resolved extinction profiles demixing phenomena are quantified regarding clarification velocity, sedimentation and flotation velocity of particles, residual turbidity, separated phase volume (liquid or solid), sediment consolidation or dewaterability.

------------------------------------------------------------------------------------------------------------------------------------------------------------

Furthermore, comprehensive infomation is obtained with respect to the multimodality or polydispersity of dispersed particles.

The choice is yours

Understand and differentiate between the various stability and instability processes, all performed in-situ, across your whole sample from top to bottom, at real world concentrations and under real world conditions.

Measure stability, particle size distributions, sedimentation/creaming and clarification rates, calculate shelf life, fingerprint your product, look at coagulation/coalescence, measure flocculation rates and floc strength, observe the thickness and density of your sediment/creaming layer, study colloid crystallization, and much more.

Measure, understand, predict, and then create the perfect dispersion for your application.

Whether it is for research and development, quality control, or product optimization, the LUMiSeries puts you light years ahead of your competition. The LUMiSeries consists of the LUMiReader PSA & LUMiReader X-Ray, LUMiFuge, LUMiSizer and LUMiFrac (for composite materials).

STEP-Technology® – giving you the edge in dispersion analysis and formulations.